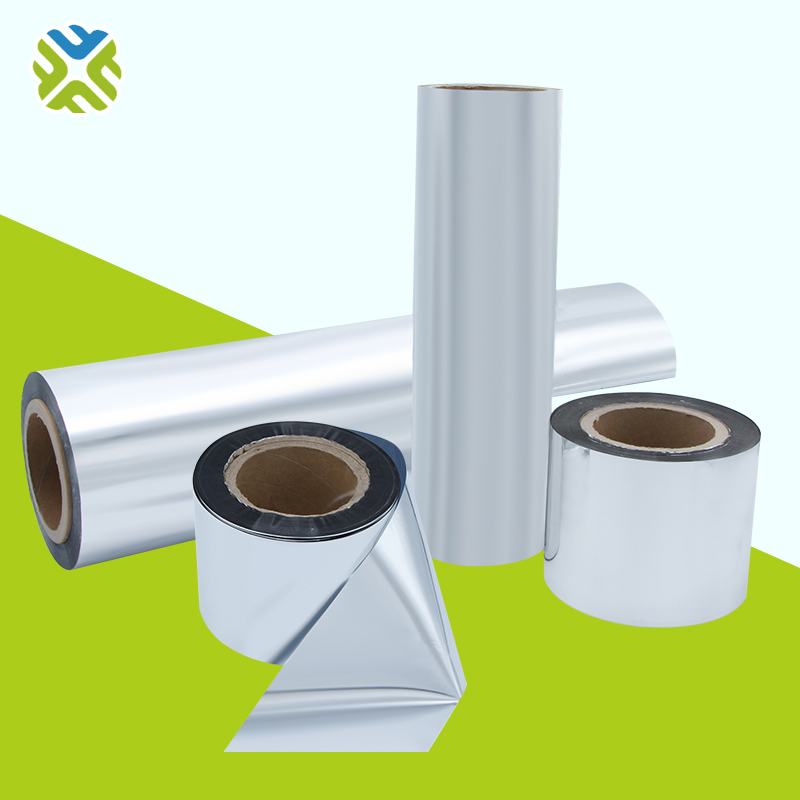

When choosing pet release film, the appearance of the product has always been valued by many buyers. However, there are many reasons that can lead to unsatisfactory product appearance. Let's take a look at what factors affect the appearance quality of pet release film?

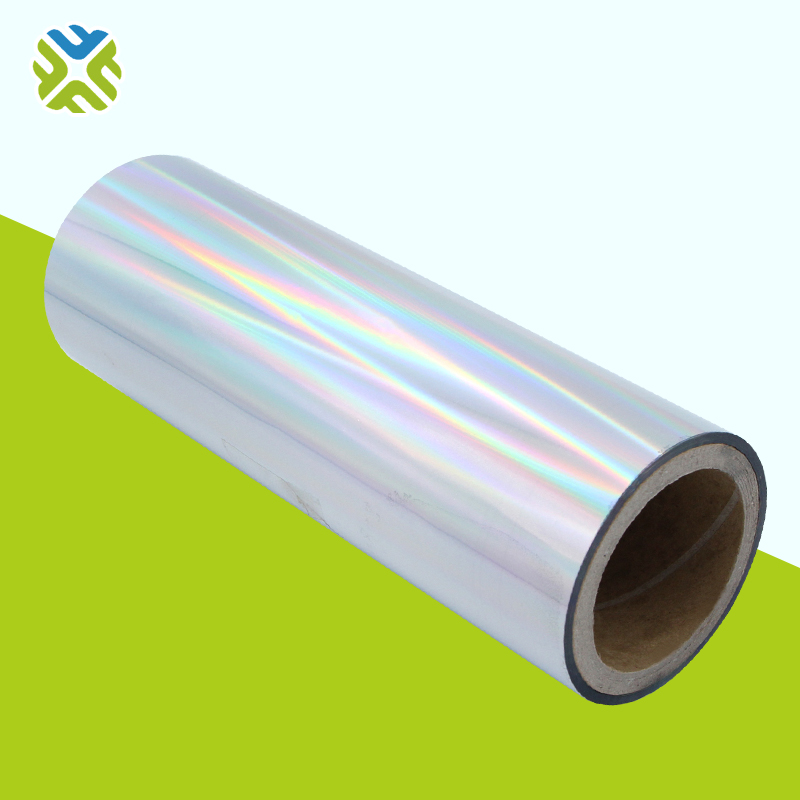

Rainbow pattern - the key first step:

The release film and rainbow pattern are not related at all, but since the silicon coating, the two have been inseparable, so whether there is rainbow pattern has become the key first step to investigate the release film.

The solvent is the main reason for the formation of rainbow lines. In the production process, in order to reduce the coating amount as much as possible, it is necessary to add more solvent oil, and the direct result is that the solvent oil on the release paper is more than silicon oil. In the process of hot drying, the solvent oil volatilizes, leaving a rainbow pattern.

If we need to paste 3M TESA and other high adhesive tapes, or if we need to punch very small shapes, we must choose the appropriate release paper. Because the shape of the punching material is very small, a very light release force is required, but if the release force is too light, it will fly off in the punching process and change its position. The high-grade industrial tape we use in daily life is basically oil glue, so the requirements for release film are very high. Whether there are rainbow lines directly affects the applicability of the tape.

Address:A2110, Tianrun Building, Dongfeng Street And Jinma Road, High-Tech Zone

Address:A2110, Tianrun Building, Dongfeng Street And Jinma Road, High-Tech Zone

Mobile:+8615169643109

Mobile:+8615169643109

Phone:+8615169643109

Phone:+8615169643109

Whatsapp:+8615169643109

Whatsapp:+8615169643109

Wechat:15169643109

Wechat:15169643109